PrintAbility Project

In the Spring of 2014, Dr. Matt Ratto, Director of the Semaphore Lab at the University of Toronto approached me about a project to 3D print below-the-knee prosthetic sockets for children in the developing world. Matt was working with CBM Canada, an international NGO, which funds a rehabilitation hospital called CoRSU in Uganda. The idea was to apply inexpensive consumer-level 3D printing to improve access to prosthetics in the developing world. A preliminary grant was awarded by Grand Challenges Canada to explore this problem space, as part of their 2014 Stars in Global Health program.

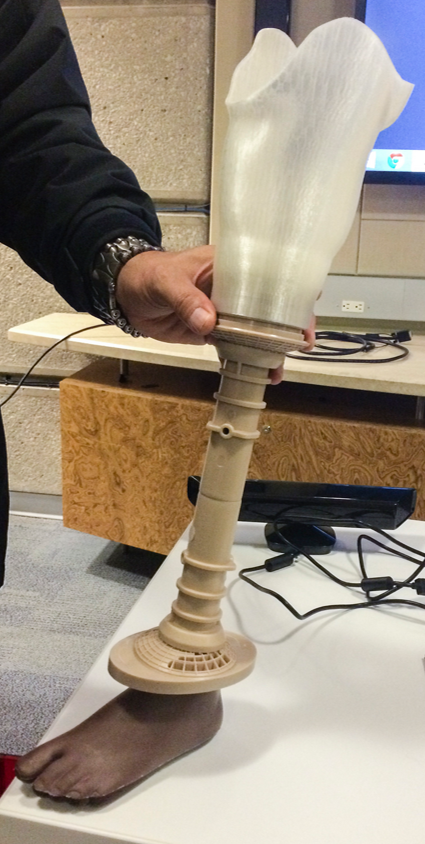

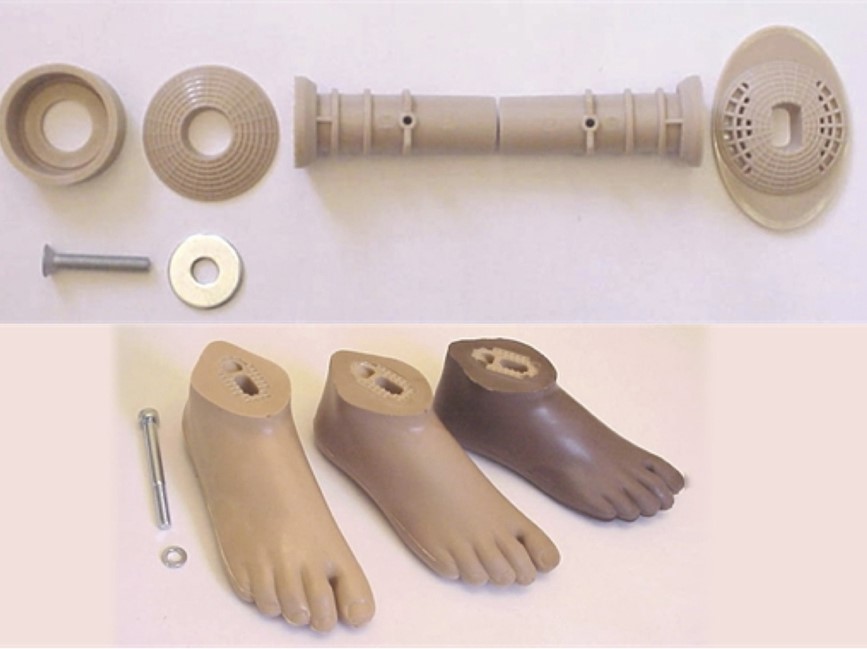

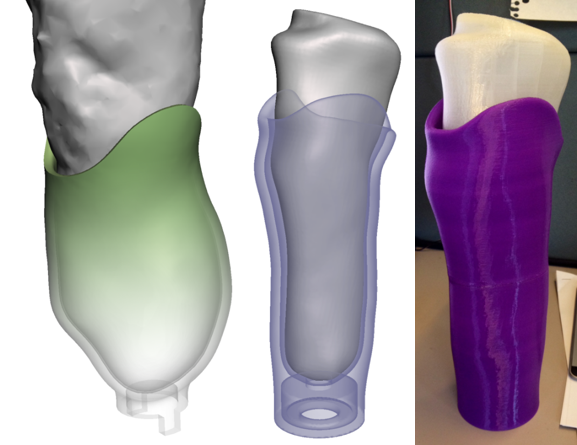

Standard FDM 3D-printed plastics are comparable to the plastics used for prosthetics and orthotics in developing world contexts, so the main problem was socket design. The prosthetic socket must be form-fit to the patients residual limb, which is usually accomplished via plaster cast and vacuum-forming. This often takes upwards of a week to complete. Our goal was to reduce this time to one day. Since there are so few prosthetic technicians in developing-world countries (only 12 in Uganda, at the time!!), such a throughput improvement would vastly improve availability of prosthetics, particularly for children who require frequent replacements .

Matt and his students had developed a scanning process for residual limbs, but turning the scan into a functional socket was quite difficult in standard CAD tools. And the system ultimately needed to be usable by prosthetists with minimal-to-no CAD experience. So we turned to Meshmixer, the CAD tool I was developing at Autodesk.

To support the project I added several new Meshmixer capabilities, such as the now-widely-used Offset tool, and also the scripting API was significantly expanded. Working with Matt's students ginger coons and Vincent Chen, we developed SocketMixer, a "wizard" that simplified the prosthetic design process. I presented details about the socket design at SIGGRAPH 2015, my slides are available here.

Once the system was functional, CBM organized a visit to Uganda to set up a trial deployment at CoRSU. Initially we were scheduled to go in October 2014, but due to an out break of Marburg hemorrhagic fever (!!!) the trip was delayed until January 2015. I traveled with the team to Uganda, primarily as a trouble-shooter for any technical issues. In the end I mainly tended to the hardware, producing variants of Rosaline's socket until we got one the prosthetists were happy with.

This project was widely covered in the news media, articles were written by Toronto Star, CBC News, Forbes, and Global News, among others. BBC Health visited and did a story while we were in Uganda, and David Suzuki's famous Canadian TV show The Nature of Things also included our project in one of their episodes. In both cases, the back of my head figured prominently.

However, I did have my 15 minutes of fame - I was interviewed on Click, a radio show on the BBC World Service, which has over 100M listeners. Not bad.

Nia Technologies

The initial Uganda deployment was a successful field trial of the system, with over 30 children receiving printed sockets. As a result of this successful experiment, Canada Grand Challenges approved a $1.5 million grant to scale up the project. An independent non-profit named Nia Technologies was formed and additional grants were provided by Google.org and the Autodesk Foundation. This funding enabled the further development of Nia's prosthetics design/print pipeline. The Nia team has returned to Uganda, as well as setting up a site in Cambodia in April 2016, and another in Tanzania in October 2016.

Currently I have an advisory role in the project, assisting Nia Technologies with technical hardware and software issues.